Fully Automatic paper bag making machine

Square Bottom Paper Bag Making Machine

V Bottom Paper Bag Making Machine

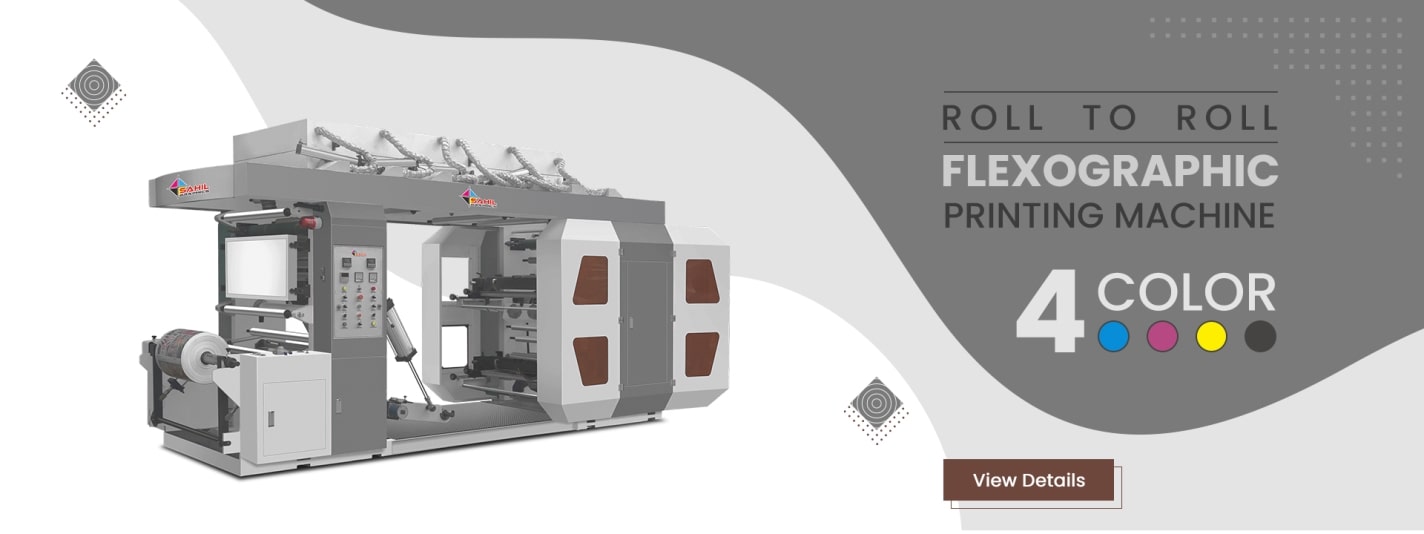

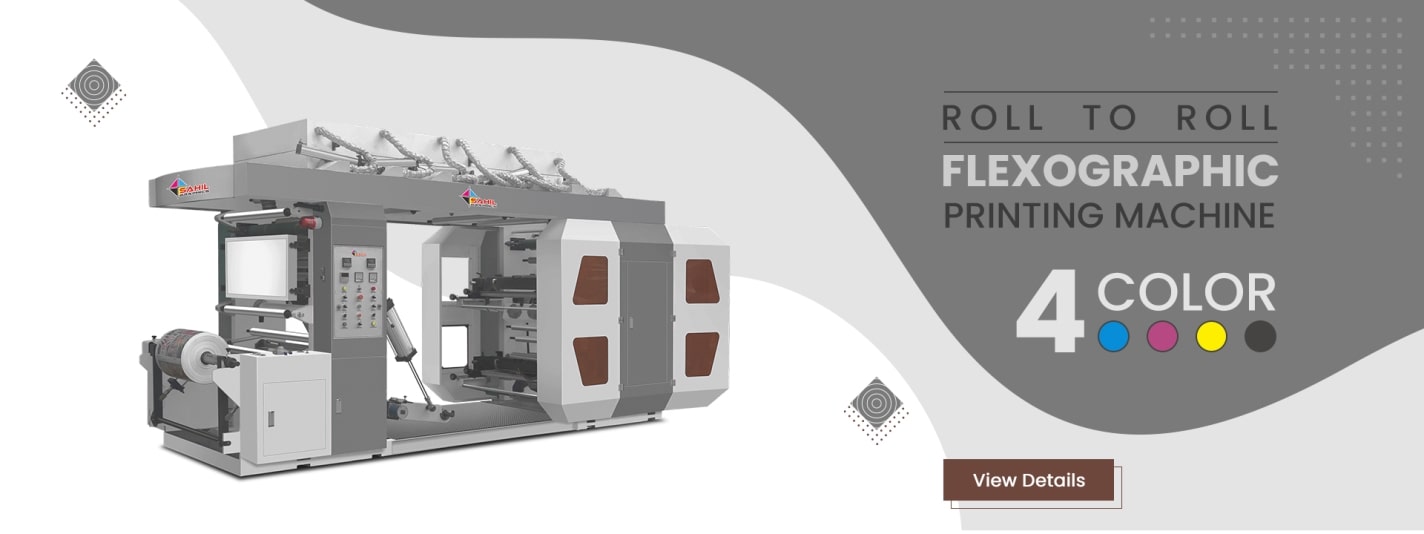

Flexographic Printing Machine

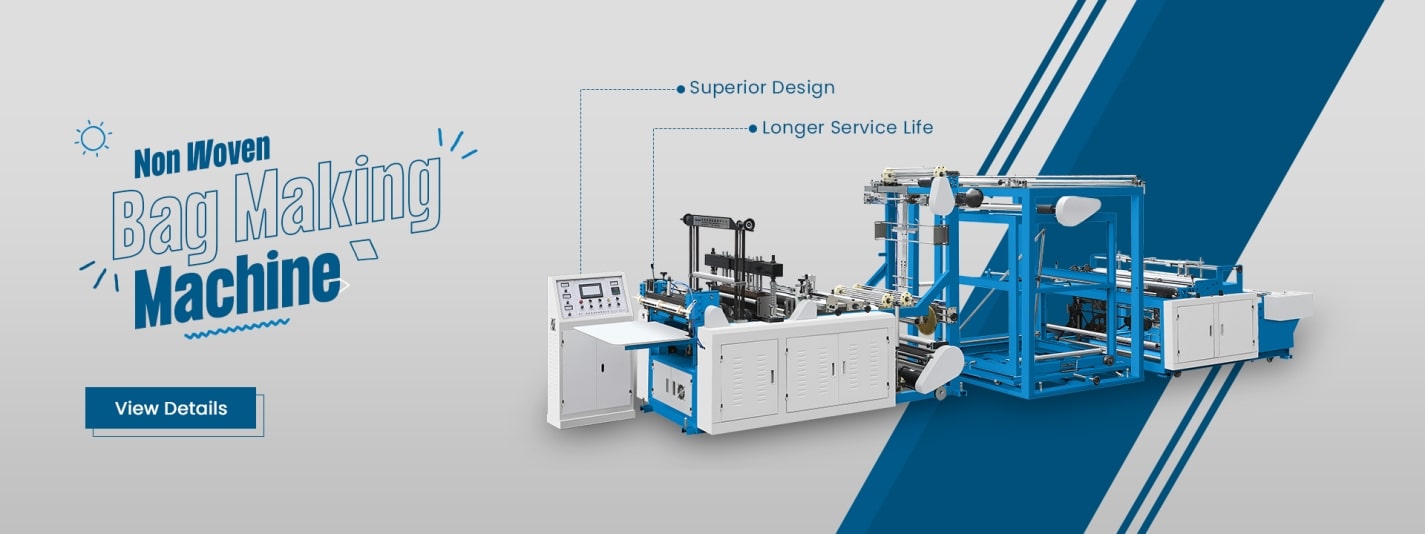

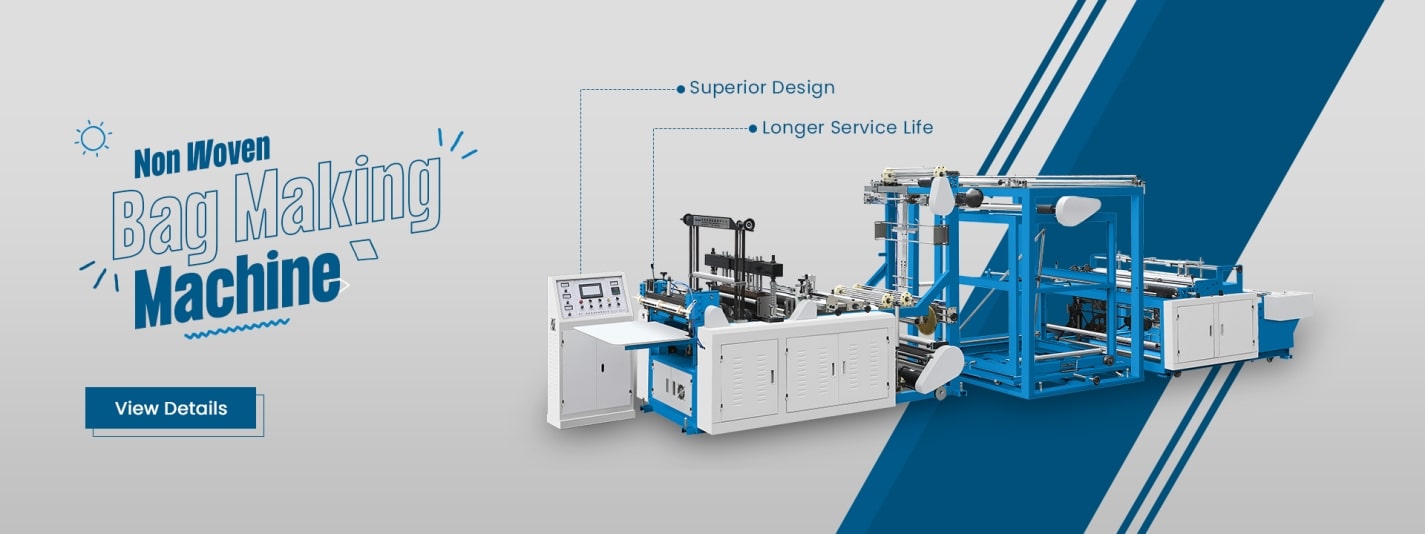

Non Woven Bag Making Machine

Ecommerce Paper Bag Machine

Sahil Graphics, established in the year 1998 is the #1 Manufacturer and Exporter of Automatic paper bag making machines and flexographic printing machines in India with over 250+ machines running across the globe. We specialize in a single color, 2 color and 4 color sheet fed offset printing machine, Non Woven Bag Making Machine, Non Woven Printing Machine.

At Sahil, We work on three principles - Quality, Commitment, and Services. Customer's satisfaction is always our prime priority. More than 2000+ happy customers across PAN India and globe.

We appreciate the loyalty and patronage of our clients and thank all those who have taken the time to write to us either to commend us or to suggest ways to improve our services. Below are some excerpts of letters and email messages we have received over the years.