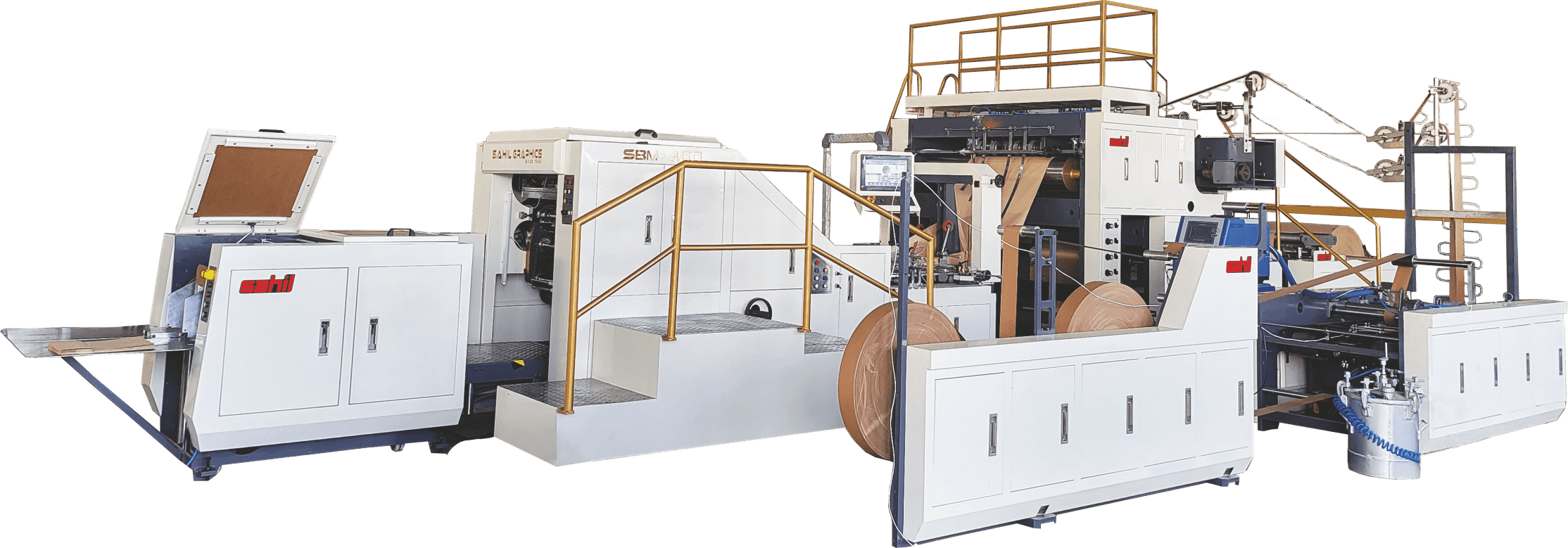

Fully Automatic Twisted Rope Handle Square Bottom Paper Bag Machine combines precision engineering and innovative features to streamline the bag-making process. With this machine, you can effortlessly produce square bottom paper bags with sturdy twisted rope handles, meeting the growing demand for eco-friendly and stylish packaging solutions.

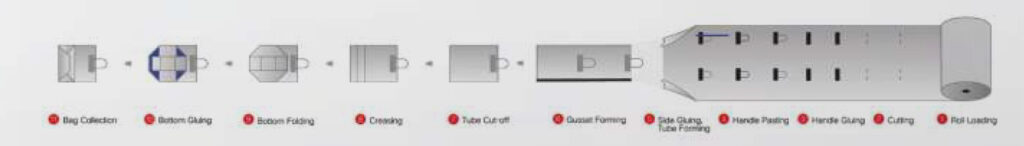

Process Flow Chart

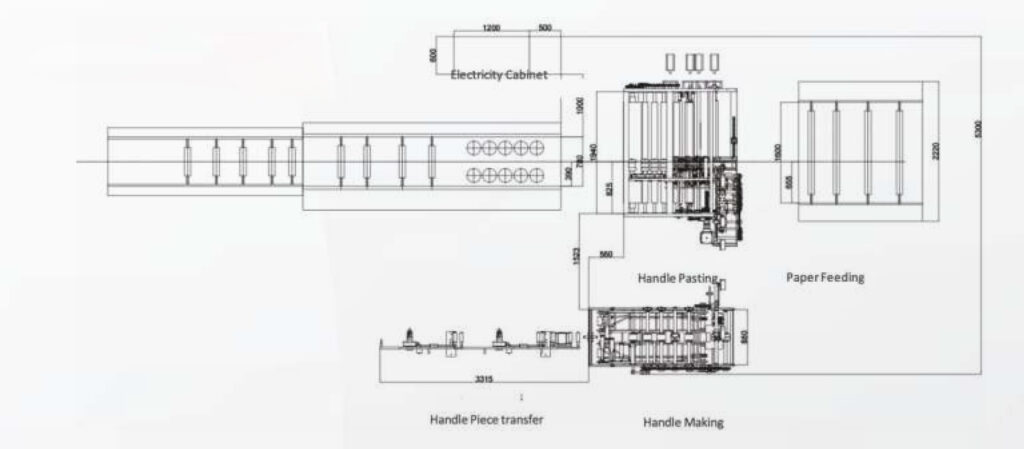

Schematic Diagram

High Productivity: The machine is designed for high-speed production, allowing you to generate a large volume of finished bags in a short period. This enhances your overall production efficiency and helps meet customer demands.

Precise Bag Making: Our Fully Automatic Square Bottom Paper Bag Making Machine With Handle ensures accurate and consistent bag dimensions, ensuring uniformity and professional aesthetics. The square bottom design offers increased stability, making the bags suitable for various applications, including retail, food service, and promotional purposes.

Twisted Rope Handle Application: The fully automatic square bottom paper bag making machine application system integrated into the machine simplifies the handle attachment process. It ensures secure and reliable handle placement, enhancing bag durability and usability.

Versatile Bag Specifications: Our machine accommodates various bag sizes, allowing you to cater to a wide range of packaging requirements. Whether you need small boutique bags or large shopping bags, the machine can adapt to your needs with ease.

User-Friendly Operation: The machine incorporates user-friendly controls and an intuitive interface, making it easy for operators to set parameters, monitor production, and perform maintenance tasks. Minimal training is required to operate the machine efficiently, reducing downtime and increasing productivity.

Quality and Durability: We understand the importance of producing high-quality bags that reflect the value of your brand. Our fully automatic paper bag machine in India is built to meet stringent quality standards, ensuring durable and visually appealing bags that leave a lasting impression on customers.

Energy Efficiency: Our machine is designed with energy-saving features, optimizing power consumption without compromising performance. This not only reduces operational costs but also aligns with sustainable manufacturing practices.

Contact us today to learn more about our Fully Automatic Twisted Rope Handle Square Bottom Paper Bag Machine and how it can transform your bag production process. Experience the efficiency, reliability, and quality that our machine brings to your packaging operations.

Manufacturing facilities:

In order to produce high quality machines a high class cnc centre has setup in factory facility supporting on production to ensure high precision standard on parts such as main frame structure, big drum,middle clip,side claws which need very high core density.We invest on high level CNC center.

| Bag width | 220-460mm |

| Paper Thickness | 60-150GSM |

| Max. Bag bottom width | 100-200mm |

| Tube length | 260-430mm |

| Rolled paper width | 625-1350mm |

| Rolled paper diameter | 1300mm |

| Inner diameter of paper | 76mm |

| Total power | 15KW (3Phase) |

| Air pressure | 690KPA |

| Net weight | 7500KG |

| Max. speed | 30-150pcs/min |

| Dimension approx. | 15*8*2.6m |

| Round rope technical parameter | |

| Handle paster length | 190mm |

| Handle paster width | 50mm |

| Paper rope spacing | 95mm |

| Handle paper rope diameter | 3-5mm |

| Handle poster paper roll width | 100mm |

| Handle paper roll width | 1000mm |

| Handle paster gram per square meter | 80-135g/m2 |

MACHINE PARTS

The complete machine is divided into 4 parts as follows:

2. Bag forming unit.

3. Handle Making unit

4. Handle sticking unit

5. Delivery conveyor unit.

6. Machine electrical panel

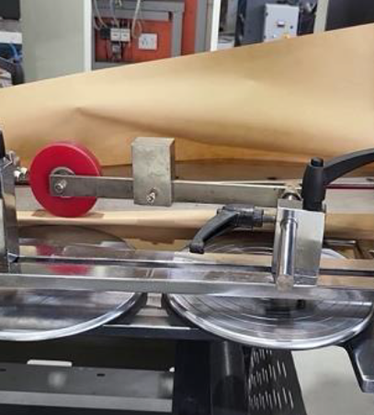

Automatic side glue dispensing system provides exact amount of glue required with respect of different quality of paper. It also ensures, dispensing exact amount of glue required with the speed of running paper.

Part 2 Paper bag forming unit

Part 3 Handle Making Unit

Two rolls of raw paper and paper rope are fed together, and the roll of raw paper and the wound round paper rope are glued with water glue and hot glue; then the hand-pull sheet is conveyed and pressed by the pressing device; The handle is cut in half and sent to the sticking mechanism.

| Side glue system | Spray glue | 1 Set |

| Handle machine hot melt | glue machine | 1 Set |

| Servo motor drive | Mitsubishi, Japan | 1 Pc |

Part 4 Handle sticking unit

Cut the delivered handle piece and then transfer it to the longitudinal push claw; the offset station will send the cut handle to the designated position of the bag mouth where the paper bag is to be produced; then give the handle and the paper bag a designated position. Water glue and glue, then press and fix the handle pasted on the paper bag and transfer it to the forming unit.

| Hand glue system | Automatically add glue | 1set |

| Handle detection electric eye | Panasonic | 1pc |

| Drive Servo motor | Mitsubishi , Japan | 1pc |

| Stab Servo motor | Mitsubishi , Japan | 1pc |

| Gluing Servo motor | Mitsubishi , Japan | 1pc |

| Transmission Servo motor | Mitsubishi , Japan | 1pc |

5. Machine Material

| Tube former material | Stainless steel |

| Shaft material | EN 8 hard chromed |

| CAMS materials | EN24, EN31 |

| Roller | Anodized aluiminium , stainless steel |

| Cutter roller assembly | Dynamically balanced |

| Central drum | Assembly Dynamically balanced with hard chromed |

| Lubrication | Centralized automatic cooling |

| Part 6 Finished bag collection unit |

| The formed paper bags are pressed and conveyed out of the belt. The bag collecting unit receive the data from plc and can stack bag produced in desiredquantity. |

| Automatic detection of electric eyesAutomatic counting photo eye |

Part 7 Machine Electrical panel

The electrical panel of the machine can be named the brain of the machine in simpleterms. It is equipped with best in class quality of components to deliver seamless work performance. It is also equipped safety devices which safeguards the machine from easily being damage.

Component used in the machine are as follows. Automatic fault detection function

This function is mainly used when the machine is running in a normal high-speed state, if an unexpected situation occurs, the machine can be automatically stopped immediately to avoid unnecessary losses.

2. Automatic refueling system

The system is mainly to automatically supply oil to the machine when it is running, to

ensure that the gears of all parts of the machine are well lubricated, so that the machinecan exert better performance under long-term operation

| Part 8 Component coatings |

| The thickness of the shaft Hard chromeplating layer < .1 mm |

| Part 9 Others |

| Fastening screw materials UNBRAKO (USA) Conveyor belt material PTG Bearing SKF (Switzerland) Pneumatic components JANATICS |

| S no | Model | Series A - 360 | Series A - 460 | Series A - 460 L |

|---|---|---|---|---|

| 1 | 1: Paper bag part | |||

| 2 | Cutting Length C | 270-530mm 270-480mm(Handel) |

270-530mm 270-480mm(Handel) |

270-530mm 270-480mm(Handel) |

| 3 | Bag Width W | 120-330mm 200-330mm (Handle) |

220-450mm 240-450mm (Handle) |

220-450mm 240-450mm (Handle) |

| 4 | Bottom Width H | 80-200mm 80-180mm (Handle) |

80-200mm 80-180mm (Handle) |

80-220mm 100-220mm (Handle) |

| 5 | Paper Thickness | 60-140 gsm 80-140 gsm (Handle) |

80-140 gsm 80-140 gsm (Handle) |

80-140 gsm 80-140 gsm (Handle) |

| 6 | Paper Roll Maximum Width | 1050mm | 1290mm | 1370mm |

| 7 | Roll Paper Diameter | 1200mm | 1200mm | 1200mm |

| 8 | Paper Core | 78mm | 78mm | 78mm |

| 9 | 2: Rope Handle part | |||

| 10 | Patch Lengtn a | 152mm | 180mm | 180mm |

| 11 | Patch Widtn b | 45-50mm | 45-50mm | 45-50mm |

| 12 | Handle Rope Height d | 100mm | 100mm | 100mm |

| 13 | Handle Distance c | 75mm | 95mm | 95mm |

| 14 | Rope Diameter | 3-5mm | 3-5mm | 3-5mm |

| 15 | Patch Paper Roll Widtn | 90-100mm | 90-100mm | 90-100mm |

| 16 | Patch Paper Roll Diameter | 1000mm | 1000mm | 1000mm |

| 17 | Patch Paper Thickness | 100-130gsm | 100-130gsm | 100-130gsm |

| 18 | 3: Specification | |||

| 19 | Production Speed for Bags Without Handles | 30-180 bags/min | 30-180 bags/min | 30-185 bags/min |

| 20 | Production Speed for Bags With Handles | 30-140 bags/min | 30-120 bags/min | 30-110 bags/min |

| 21 | Bottom Folding Type | |||

| 22 | Cutting Knife | Teeth Cutting | ||

| 23 | Power Supply | 380 V 3Phase 40KW | 380 V 3Phase 40KW | 380 V 3Phase 43KW |

| 24 | Machine Weight | 13.5T | 14.5T | 16T |

| 25 | Machine Size | 15000X6000X2700mm | 17000X6000X2700mm | 17000X6000X2700mm |