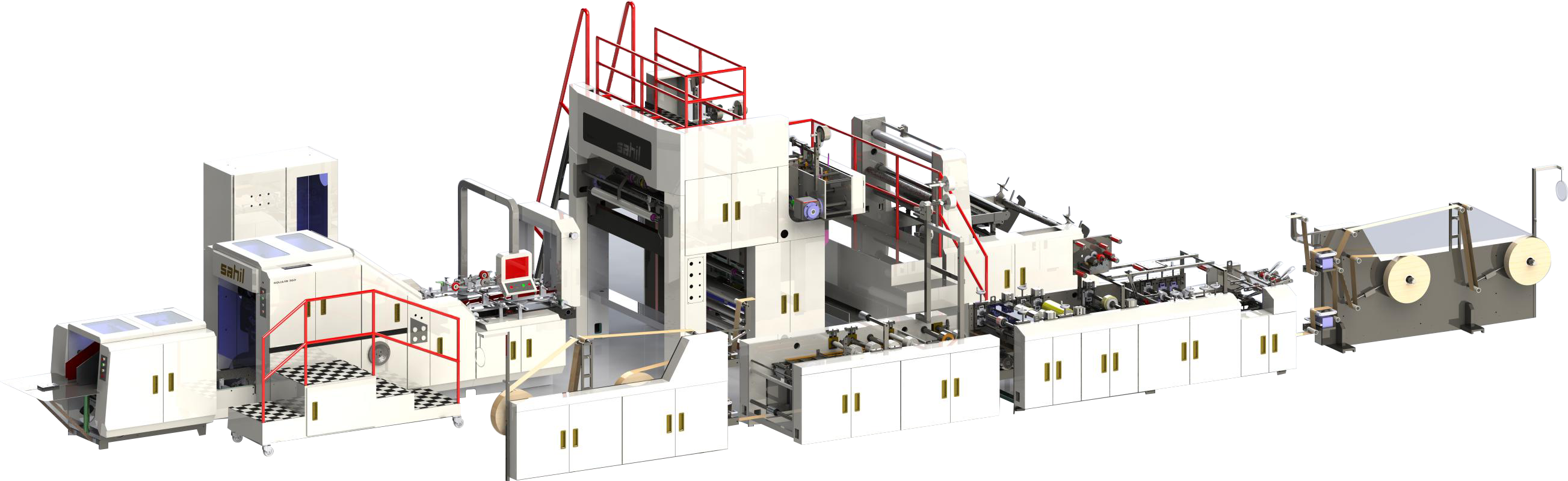

Courier Paper Bag Making Machine

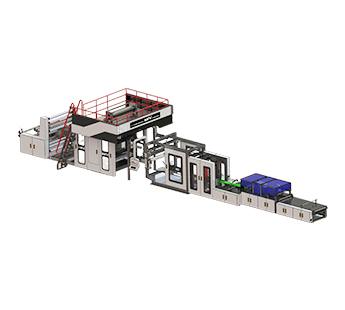

E- Comm-1 produces e-commerce peel and seal paper bags with cold glue technology. This new generation Ecommerce Paper Bag Making Machine design gives you highest freedom of bag size range where high production and low operating expense are assured. Online printing makes machine universal and completes bag with printing & Taping in a single pass.

Sample box

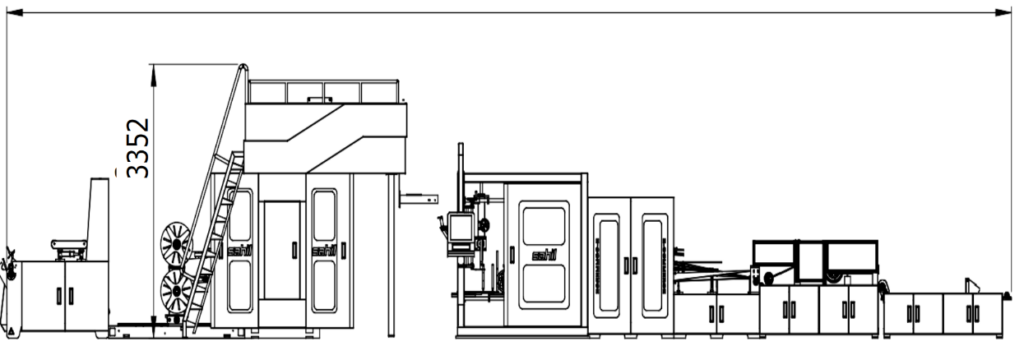

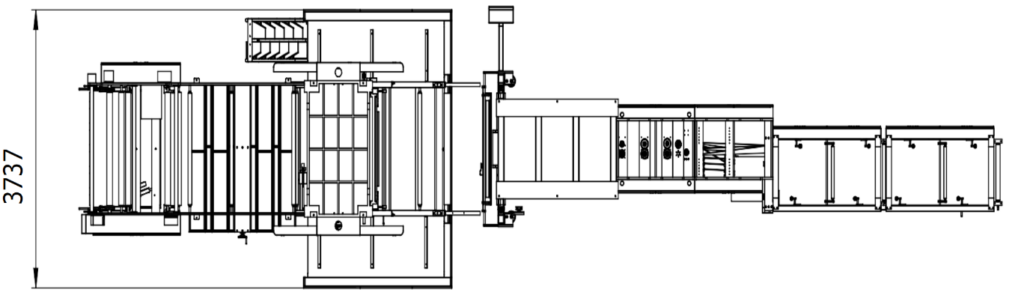

Machine Diagram

| TECHNICAL PARAMETERS | |

|---|---|

| Cutting Length | 170 MM – 650MM |

| Bag Height | 60MM – 625MM |

| Bottom Width | 0 – 150MM |

| Cold Glue Section | 1 |

| Speed | 150 – 200 BAGS/PER MIN |

| Web Guide | AUTOMATIC |

| Max. Roll Weight | 700KG |

| Max. Roll Width | 1400MM |

| Tension Control | AUTOMATIC |

| Peel & Seal Mechanism | HOT MELT WITH 2 RELEASE TAPES |

| Power Consumption | 20KW |

| Flexo Printing Station | 2 COLOR |

| Type of Glue for Bags Side Sealing | COLD GLUE |

| Control System | COMPLETE SERVO DRIVEN |

| Machine Dimension (L x W x H) | 19000MM X 4200MM X 3100MM |

UNWIND SECTION

- Roll weight of max 700kgs

- Automatic tension control with load cell

- Dancer based feed back

- Air shaft

PRINT AND GLUE SECTION

- 2 stations of printing with water based inks

- As an option: 1st station can be printing & 2nd station can be water repellent coating

- Hot air drying plus IR drying

- 1 station of cold glue

- Glue section will be servo driven for variable repeats

- Print section will be servo driven

- Eye mark sensor for gluing mechanism with offset function

- Closed Chamber Doctor blade for printing stations

- Single Roller web guide

- Double Release Tape with perforation for tear tape

INFEED & OUTFEED SECTION

- Servo Driven load cell based Infeed section for optimum tension control

- Servo Driven Load Cell based outfeed section for optimum tension control

FORMING SECTION & CUTTING SECTION

- With and Without Gusset

- Pasted Flat Bottom servo driven

- 2 nips driven by individual servo motor

- Cutting section servo driven

CONVEYOR SECTION

- Independent motor driven conveyor belt

- Large diameter Pressing roller

- Edge Sensing counter

- Kicker system for batch

- Variable batch setting provision

Connect Now!

Machine Specifications

| S no | Parts of name | Brand’s name | rand’s country | |

|---|---|---|---|---|

| 1 | 7 Axis Motion Controller |  |

JAPAN | |

| 2 | Main traction servo |  |

JAPAN | |

| 3 | Cutting servo |  |

JAPAN | |

| 4 | Traction servo drive |  |

JAPAN | |

| 5 | Cutting servo drive |  |

JAPAN | |

| 6 | Pulling Servo motor |  |

JAPAN | |

| 7 | Stab Servo motor |  |

JAPAN | |

| 8 | Gluing Servo motor |  |

JAPAN | |

| 9 | Transmission Servo motor |  |

JAPAN | |

| 10 | Pulling Servo drive |  |

JAPAN | |

| 11 | Stab Servo drive |  |

JAPAN | |

| 12 | Gluing Servo drive |  |

JAPAN | |

| 13 | Transmission Servo drive |  |

JAPAN | |

| 14 | Contractors |  |

FRANCE | |

| 15 | Drive bearing |  |

SWITZERLAND | |

| 16 | Glue dispensing unit |  |

JAPAN | |

| 17 | PLC |  |

JAPAN | |

| 18 | MCB |  |

FRANCE | |

| 19 | Eye Mark Sensor |  |

GERMANY | |

| 20 | HMI (15inch) |  |

JAPAN | |

| 21 | Relay Card |  |

JAPAN | |

| 22 | Proximity Sensor |  |

JAPAN |